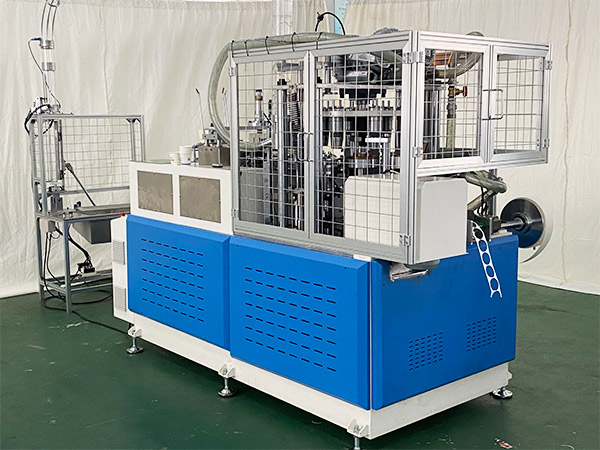

Model:FYC-03

Speed:120-150 PCS/minute.

Cup Size:3~16oz.

Material:One or Two side PE coated paper,140~350gsm.

The design concept:automatic ,simple, compact and stable.

Production use reference: all kinds of household paper cups, various capacity and styles paper cups.

The machine can finish the whole process including paper feeding, side sealing, cup bottom punching & feeding, heating, knurling, cup-top curling, cup stacker. It is the best choice for making paper cups. The company can also customize and produce various specifications of paper cup machine and paper bowl machine molds according to customer requirements.

The encoder and the optical eye control the machine at the same time, and a fan-shaped piece is equipped with a cup bottom to avoid waste. Fault alarm, automatic shutdown.

In the past, the complicated process of sucking and feeding the bottom paper was prone to turn the bottom. The equipment was changed to use a direct bottom flushing and bottom feeding method to avoid turning the bottom in one step.

The machine uses PLC control, which improves intelligence and makes the stroke more precise and accurate. Reduce people

The inner part of the machine is connected by sheave wheels, and all parts are connected more tightly, so that the machine is not easy to loosen during the operation of the machine, and the work is more precise.

Ultrasonic welding system is adopted,and multiple fans operate at the same time to increase heat dissipation and speed up cooling, soas to keep the machine at appropriate temperature duringoperation.

|

Speed: 120-150/minute, Open Cam instead of gear box Precise gears transfer motion instead of chain |

|

|

Material: One or Two side PE coated paper, 140~350gsm, Cup Size: 3~16oz, |

|

|

|

Top: 50~95mm

Bottom: 35~75mm

Height: 50~140mm |

|

Actual Power: 4 KW, Electricity: 50/60Hz, 380V 3-phase, Total Weight:2100KG Size: L2535*W1350*H1760 mm |

|