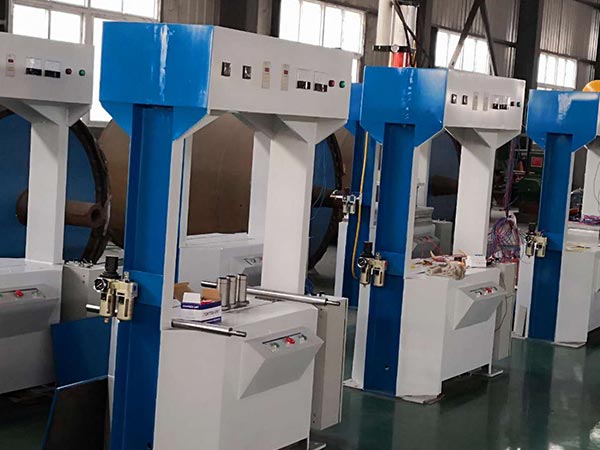

Model:15 Tons Hot Press Machine

Hot Press Mould:Customized

Working pressure:0.55~~0.65MPa

Mold High:≤150mm

Pulp molding equipment mainly includes equipment for producing pulp molded products consisting of hydraulic pulpers, forming machines, shaping machines, plus supporting equipment such as air compressors, vacuum pumps, and pulp pumps. The hot press shaping machine is a device that smoothes the geometric shape of the dried paper support through the special hot press mold through the equipment heating, pressurizing and other actions.

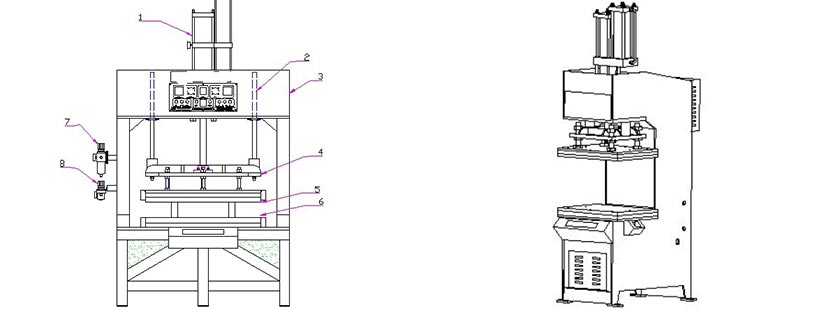

1.Cylinder 2. Guide rod 3. Frame 4. Adjusting plate 5. Upper template

6. Lower template 7. Triple body 8. Pressure regulating valve

-------------------------------------------------------------------------------------------------

1.Sending design 3D drawings or samples

2.Select material

3.Open molds

4.Forming molds

Open mold customization, carefully selected materials, acid and alkali resistance, not easy to deform, stable and strong, complete specifications, source manufacturers, intimate after-sales.

1.It is processed by high-quality aluminum , with good extrusion performance, good strength, light weight, and corrosion resistance

2.The surface of the mold is fine and smooth, the color is bright, the hand feel is smooth and comfortable, the lines are smooth, and the craftsmanship is skillful.

3.The appearance is beautiful, the aluminum alloy is processed at one time, the whole is flawless, and the produced product is beautiful.

4.Recycling, can be used many times, stable performance, long service life, not easy to deform

5.Drawings and samples, support customized processing, many years of experience in mold opening customization, accurate mold opening.

|

Machine Model |

15 Tons Hot Press |

|

Dimensions |

(15 Tons) 980×660×1920(Mm) |

|

Table Size |

(Single Cylinder) 660×450 (Mm) |

|

Workpiece Height That Can Be Produced |

≤150mm |

|

Rated Voltage |

Ac220V ± 10% |

|

Hot Pressing Time |

0~~6 Seconds Adjustable |

|

Power |

≤7Kw |