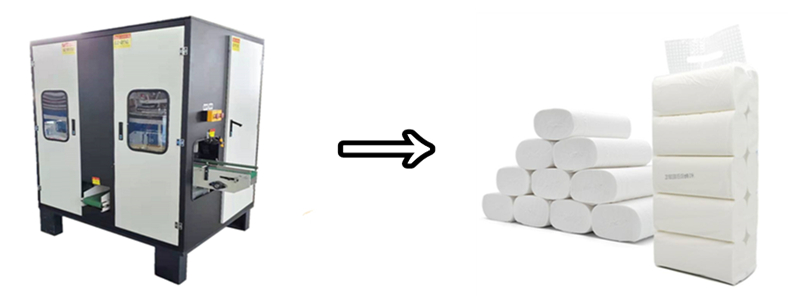

Single channel rotary paper cutter is combined with the characteristics of various kinds of household paper, the use of advanced machinery and equipment manufacturing concept, self-designed and developed toilet paper rotary machine includes paper feeding system, paper delivery system and supporting auxiliary institutions.

Safety system:

1. The equipment is installed with start alarm and fault display system.

2. Safety precautions are clearly stipulated in the equipment operation manual. On dangerous devices, obvious warning labels are posted on the equipment’s power and air transmission mechanism.

3. In the emergency stop button of the equipment, the operation of all structures of the equipment will be stopped within 1 second when the emergency stop occurs.

Electrical system:

1. The electric control cabinet door adopts rotating opening mode, wiring standard is neat and convenient for maintenance, and the electric control cabinet is equipped with axial flow fan cooling system.

2. Fixed touch screen panel, simple operation, humanization.

Pneumatic system:

1. Series solenoid valve, reduce pneumatic noise, convenient maintenance.

2. Air inlet is equipped with gas-water separator, oil mist, pressure stability regulator, the best working pressure is 0.5mpa.

3. The gas path layout is standard and reliable, neat and beautiful

Product advantages:

1. Equipped with detection eye, can automatically detect whether there is paper.

2. Conveyor belt adopts flat belt conveying, driven by an independent frequency conversion motor, conveying speed ≥ cutting speed.

3. Equipped with multiple detection eyes, used to detect the paper roll conveying state, control the rotary cutting machine.

4. High efficiency spindle servo motor is used for driving motor, man-machine interface and synchronous operating system of host equipment can be operated in the whole machine range, and personal safety can be better protected during maintenance. The whole machine has stable quality and high efficiency.